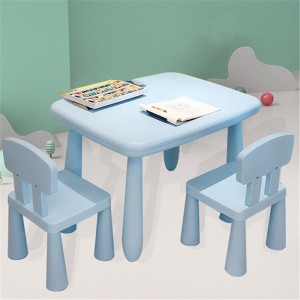

Ukuvuthela iiMolds kwitafile yePlastiki kunye nesitulo

Ingcaciso yeMveliso

Yonke iplastikhi yenkanyezi iyakwazi ukubonelela ngezisombululo ezibanzi nezihlanganisiweyo zetekhnoloji kwiintlobo ngeentlobo zezicelo zokubunjwa kokuvuthela kwinani lamashishini kubandakanya amava angaphezulu kweminyaka eli-15 kwimveliso yeplastiki ebunjiweyo. Iqela lethu lamava lifanelekile kwaye linelayisensi yokwenza iimela ezinobunjineli obuchanekileyo ezinokusika okanye ukucheba indawo ngexesha lomjikelo wokubumba. Ezi zisombululo zibandakanya ii-blade zokurhoxisa ezinobunjineli, izixhobo ezintsonkothileyo ezingenakurhoxiswa, iindlela ezinokusika imingxuma kwinxalenye ngexesha lokubumba, izixhobo zokunciphisa iindawo ezidityanisiweyo kwi-mold, kunye neendlela eziphambili. Zonke ezi zisombululo zinceda ukubonelela ukuguquguquka koyilo lwemveliso.

Xa kuthelekiswa nezitulo eziveliswe ngesitofu sokubumba, izitulo ezenziwe ngokubumba i-extrusion blowt zinezi nzuzo zilandelayo:

1. Iindleko zokubumba oomatshini bokuvuthela, ngakumbi iimbumba zokuvuthela, ziphantsi. Xa kubumba iimveliso ezifanayo, ixabiso loomatshini bokubumba bumalunga ne-1/3 yomatshini wokutofa, kwaye ixabiso lemveliso liphantsi.

2. Kwinkqubo yokuvuthela isitulo, i-parison yesitulo isetyenziselwa ukwenza isihlalo seplastiki phantsi koxinzelelo oluphantsi ngentloko yomatshini, kwaye ifakwe phantsi koxinzelelo oluphantsi. Imveliso inoxinzelelo oluncinci oluseleyo, ukuchasana nokwelula, impembelelo, kunye nokukhuselwa kwendalo. Ukusebenza kweentlobo ezahlukeneyo kuphezulu, kwaye kunomsebenzi ongcono. Xa isitulo sokubumba isitofu sibunjwa, ukunyibilika kufuneka kudlule kwimbaleki yokubumba kunye nesango eliphantsi koxinzelelo oluphezulu, oluya kubangela ukusabalalisa koxinzelelo olungalinganiyo.

3. Ubunzima bemolekyuli obunxulumeneyo bebakala lokubumba imathiriyeli yeplastiki ekrwada buphezulu kakhulu kunobo beeplastiki zebakala lokutofa. Ke ngoko, isitulo esenziwe ngokubunjwa kokuvuthela sinempembelelo ephezulu yokuqina kunye noxinzelelo oluphezulu lokuchasana nokuqhekeka kokusingqongileyo.

4. Ekubeni isikhunta sokuvuthela siqulunqwe kuphela ngumbumba wabasetyhini, ubukhulu bodonga lwemveliso bunokutshintshwa ngokulungelelanisa nje umsantsa phakathi kwe-orifice yokufa okanye i-extrusion iimeko, eziluncedo kakhulu kwiimveliso ezingenakubala ngokuchanekileyo. ubukhulu bodonga olufunekayo kwangaphambili. Iindleko zokutshintsha ubukhulu bodonga lwemveliso yokubumba inaliti iphezulu kakhulu.

5. Isitulo esibunjiweyo sinokuvelisa isihlalo esiyinkimbinkimbi, esingaqhelekanga, kunye ne-monolithic. Xa usebenzisa isitofu sokubumba, emva kokuvelisa iimveliso ezimbini okanye ngaphezulu, kufuneka zidityaniswe ne-snap fitting, i-solvent bonding, okanye i-ultrasonic welding.

Ukuchaneka kwezitulo ezibunjiweyo ngokuqhelekileyo azikho phezulu njengeemveliso ezibunjiweyo zenaliti; ukubonakala kwezihlalo ezibunjiweyo zenaliti zihlala zibuhlungu, ezichongwa ziinkqubo zazo ezahlukeneyo. Ngokubhekiselele kumbuzo wokuba yeyiphi engcono, isitulo esibunjiweyo, okanye isitulo esibunjiweyo, ndicinga ukuba kuxhomekeke kwiimfuno ezithile.